Specialty Plasma Cutting: Crafting Parts from Any Metal

In metal fabrication, precision and versatility are crucial for meeting our client requests. We wanted to bring you along the realm of specialty plasma cutting and demonstrate its capabilities through a video showcasing the creation of custom parts from different metals. Watch our video below to follow the entire process!

We begin with the fabrication of two T304 stainless steel flanges, each 3/8" thick. T304 stainless steel is a corrosion-resistant alloy known for its durability and strength. With our high-quality plasma cutting equipment, we ensure precise cuts that meet the exact specifications provided by our clients.

Next up, we move on to 6061 aluminum, a lightweight and malleable material renowned for its excellent strength-to-weight ratio. Using the same plasma cutting equipment, we transform 5/8" thick 6061 aluminum sheets into an array of parts, including flanges, lifting lugs, and more.

Lastly, we craft a diffuser from monel. We dive into the world of Monel, a nickel-copper alloy renowned for its exceptional resistance to corrosion, high temperatures, and various chemicals.

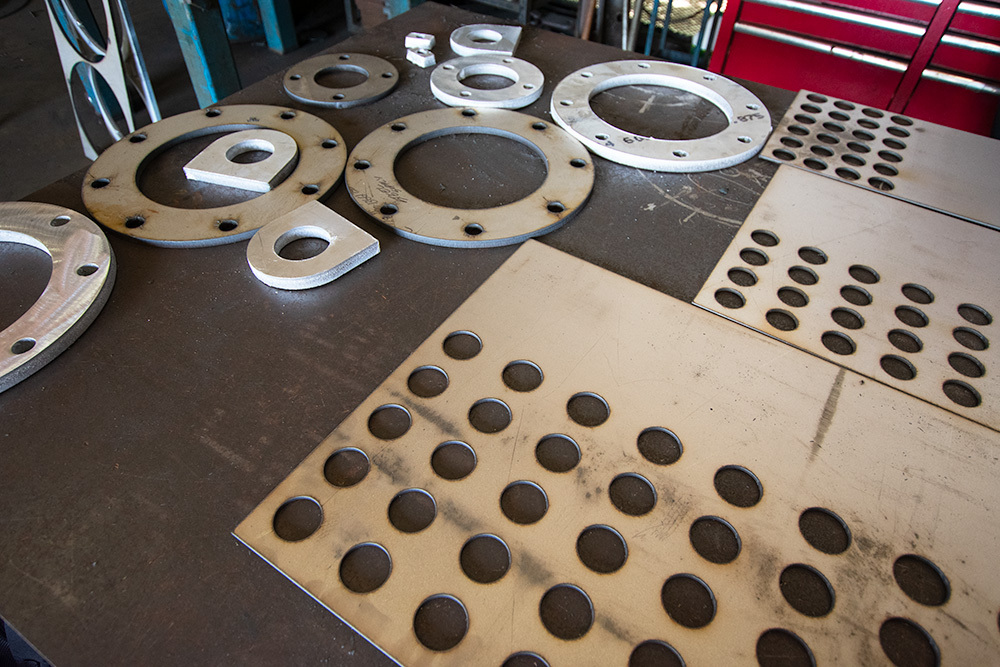

In the final picture, we present all the finished parts. But our commitment to excellence doesn't end there. After the cutting process, we ensure that each part is thoroughly cleaned, removing any residual debris and ensuring a pristine finish. Finally, the parts are carefully packed and promptly delivered to our customers.