All About Aluminum

- Strength to Weight Ratio - An aluminum beam that can support the same load as a steel beam will be larger but only half the weight. The relative yield strength to weight ratio for aluminum to steel is 2.8:1 and the raw yield strength of 6061-T6 is 35 ksi - nearly that of A36 carbon steel.

- Corrosion Resistance - Aluminum is inherently corrosion resistant. Aluminum reacts with the oxygen in the environment to create a 4nm thick layer on the surface, a process known as passive film formation. This film protects the metal from further oxidation and therefore from corroding. Anodized aluminum is a popular way of adding color and enhancing corrosion resistance. During the anodizing process, oxidation is carefully controlled to produce an extremely stable layer.

-

Cost Effective- Since aluminum is corrosion resistant it has a very low upkeep cost. Aluminum can be used without any coating in most environments. Stainless steel is similarly low maintenance however is over twice as expensive for a piece of equal strength.

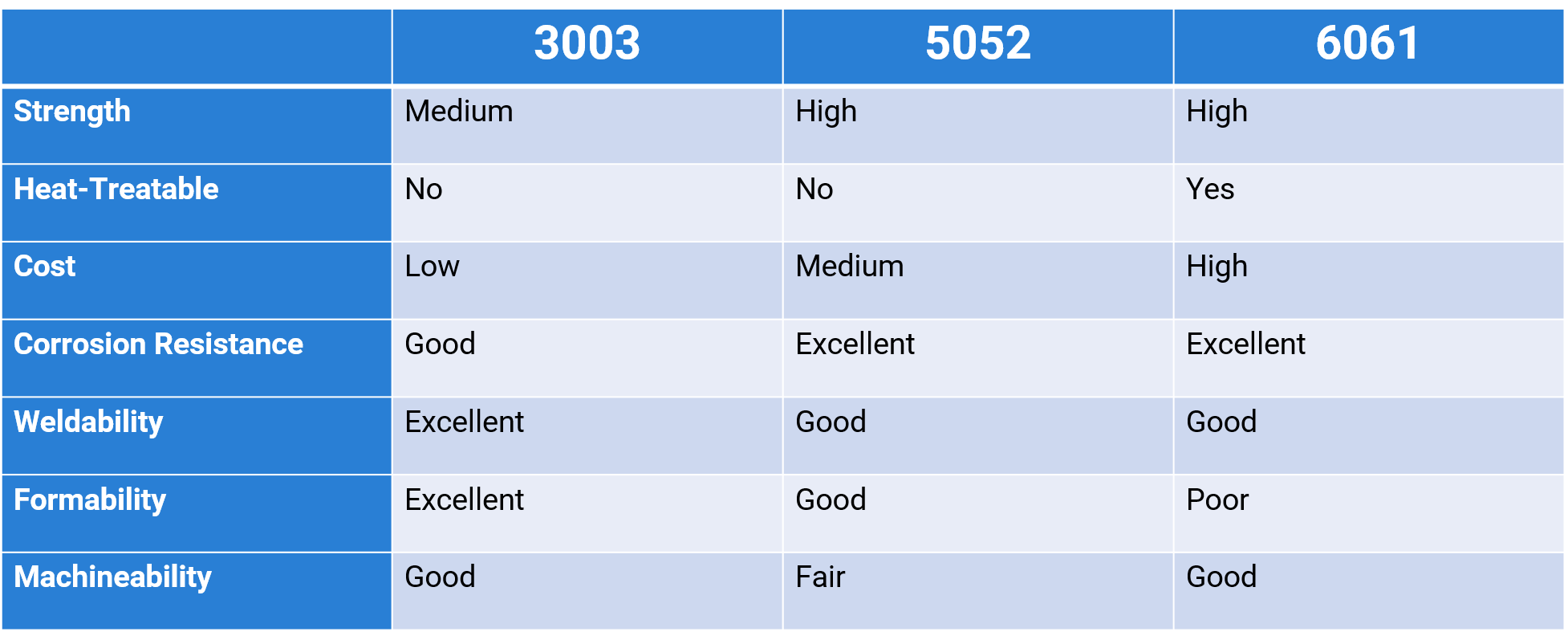

Most aluminum sold today is an alloy. That is, other elements are added to enhance the physical properties of the aluminum. Structural aluminum is typically sold in 3 different grades - 3003, 5052 and 6061. 3003 is alloyed with manganese, and is best in projects where the metal will be bent and welded. 5052 is alloyed with magnesium and has superior corrosion resistance especially in marine environments. 6061 is alloyed with magnesium and silicone, it is a very strong alloy and has excellent corrosion resistance.

Some things to look for when choosing what type of aluminum to use:

We now stock a wide variety of structural aluminum - beams, angles, channel, sheets, floor plate and more. Whether you need just one piece or an entire truck load, our sales superheros can help you get exactly what you need.