A Plasma Cutting Project

Recently, a customer placed an order for thousands of single-size cut steel parts. This project was done with our high definition plasma cutting machine. Here’s what the process of that looks like:

What is Plasma Cutting?

Plasma is considered the 4th state of matter and is most commonly associated with the Sun and other stars. It does not occur naturally in the earth’s surface, but we are able to create plasma artificially by subjecting a gas to extreme energy. The gas sheds electrons and becomes ionized. Unlike neutral gasses, plasma is very conductive. The extremely high-temperature plasma arc between the negatively charged nozzle to the positively charged workpiece cuts through metal with ease and precision. Plasma cuts are clean, precise, and reproducible. After we input a drawing into the software it converts the drawing into a path for the cutter to follow.

Stare at it long enough and you will get lost in time, but be careful because the machine gives off a broad spectrum of electromagnetic radiation, which extends from infrared light, through the visible spectrum, all the way to ultraviolet range. Needless to say, don’t look at the bright plasma arc because it can cause eye damage.

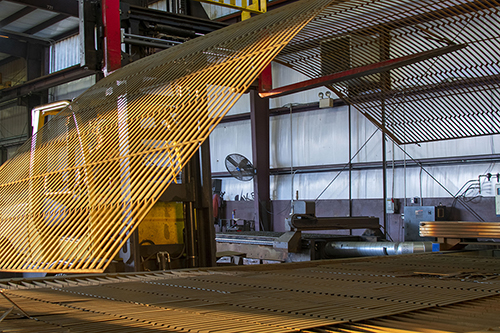

The photo above shows the first of many pieces of metal to get cut. Depending on the size of the project, it can take from a few hours to more than a day to finish. You can see each piece being cut, leaving a skeleton behind.

Here, you can see the cutting nearing completion. That is a sheet of 3/16” thick steel that is 8 feet wide and 20 feet long.

Then we gather all the steel pieces.

Afterward, we put them in a tumbler for less than 10 minutes.

After they’ve been cleaned, we stack them, palletize them, and deliver them to our customer.

Categories: Value-Added Projects, Cool Stuff