Tour of Gerdau's Midlothian Steel Mill

Some of our employees took a trip to the Gerdau Midlothian Steel Mill in Texas. Gerdau is a leading producer of long steel, beams and piling, merchant bar, rebar, and wire rod products. It is also one of the largest recyclers in North America and Latin America.

Our employees had the opportunity to take a tour, and we want to share with you what they had to say.

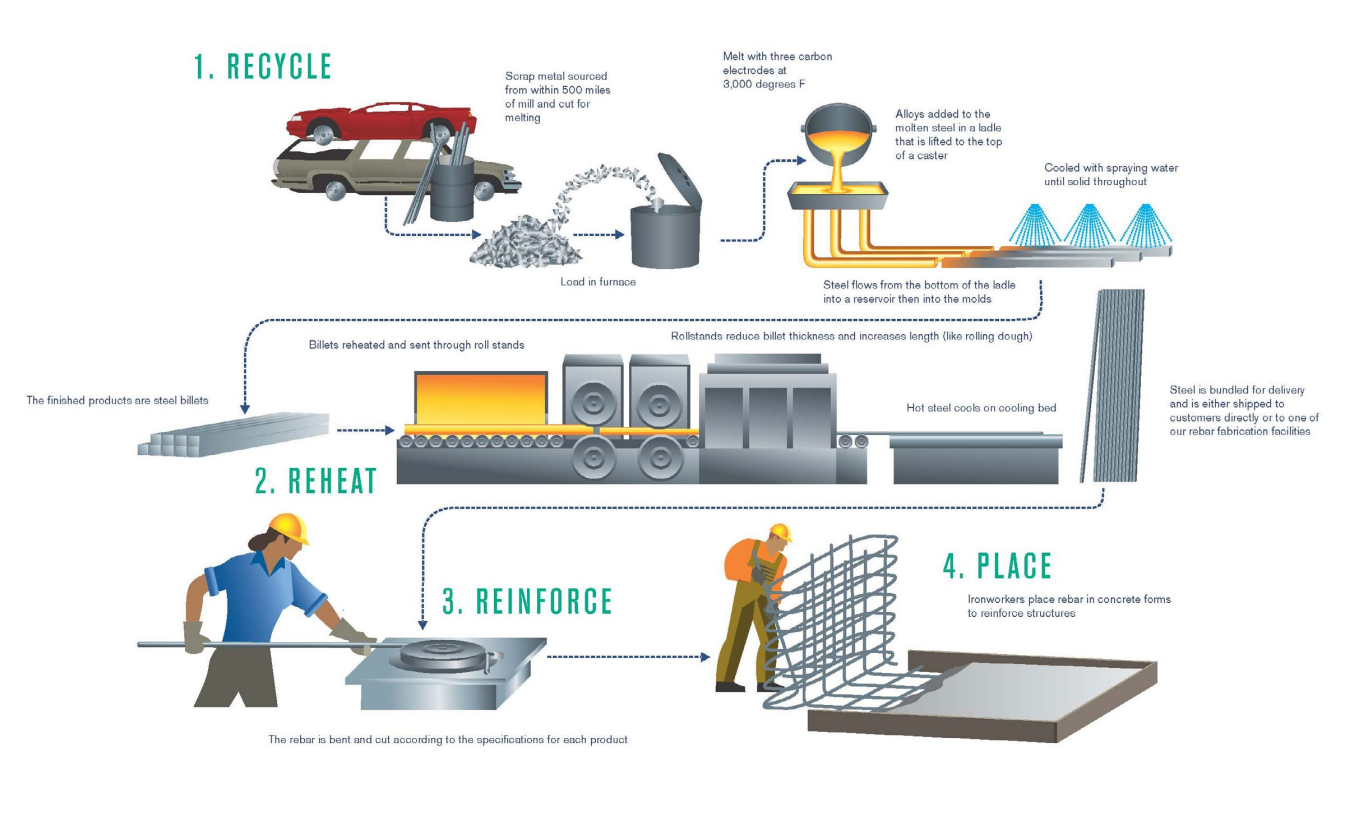

One of the tour's highlights was seeing the entire process of how Steel is made. In the image below, you can see how scrap metal, together with alloy additions, is melted in an Electric Arc Furnace to obtain liquid steel and cast into steel billets. The billets are sent to the rolling mill, where they are rolled and shaped to the required dimensions for the finished steel products.

Jessie shared that the entire process, from start to finish, was interesting. In addition, he said seeing the tour in person made it a better experience because they got to walk through the mill and see Steel being melted from a top view about 20 yards away.

Anne shared interesting facts, such as when the steel is being melted, it is about 3,000 degrees Fahrenheit. Another highlight of the Steel Mill was the importance of safety. Anne shared that the process of melting Steel is loud and at a large scale because whenever they move the crane, an alarm goes off. Thankfully they got to wear earplugs, but you can imagine how loud it was if that was necessary. Gerdau takes safety so seriously that they have a fire and safety team of about 50 people, how cool!

Ricky previously used to work for a pipe manufacturing company where the pipe was already processed and shaped. However, he found it fascinating and educational to visit Gerdau's Steel Mill because it helped him see how steel is created. "Being able to see the process of how Steel is made makes you more appreciative because of all the manpower, recycling, and environmental impact; it's so detailed, and so much goes into it," said Ricky.

Adam shared that this tour was a lot more detailed than the previous ones visited. He enjoyed the history and its conscious impact on the environment and safety. He admits it's not the same thing hearing or reading about how Steel is made compared to seeing it in person.

Michael enjoyed the process too, and how they recycle because of all the items they use, such as rims, train cargo, and junk! What stood out to him was how a 30-foot piece of billet is stretched and made into 900 feet of rebar. Another interesting fact was that from all the cars they recycled in a year, they saved up 500 thousand dollars in change found in cars.

José also shared an interesting fact about all the cars they shed, they turn into ferrous material, and any of the non-ferreous material is used to make sun-tan lotion!

Each year, Gerdau transforms more than 11 million tons of scrap into new steel products, so it is no surprise that if you visit, you will find touring their Steel Mill interesting and educational.

Categories: Cool Stuff, Everything else