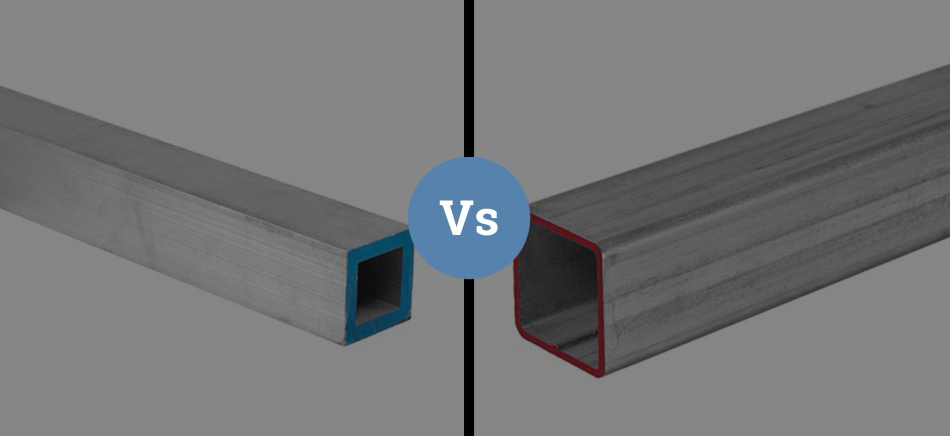

Corrosion Resistance: Aluminum vs Stainless

Below is a breakdown of the two metals and explanations about which is better for specific uses.

Weight:

- Aluminum is lighter than Stainless Steel, and Steel is typically 2.5x denser. Yet, Aluminum may dent when under intense impact or pressure compared to Stainless Steel.

- Stainless Steel does not warp, deform, or bend easily under heat or pressure.

Strength:

- Stainless Steel is robust, resilient, and stronger due to a higher tensile strength. However, Stainless Steel cannot be formed to the same dimensional limits as Aluminum because it may crack at some point due to its stiffness.

- Aluminum is more malleable and ductile than Stainless Steel. This makes Aluminum an ideal choice for applications that require forming various shapes and forms.

Corrosion Resistance:

- Stainless Steel resists corrosion, and it has a multitude of differing grades. When Stainless Steel does rust, it can be scrubbed away, and the chromium shield will renew itself. It is ideal for projects that are likely to be in contact with salt or harsh chemicals.

- All types of Aluminum are inherently corrosion resistant. Aluminum surfaces oxidize, but the oxidized layer is stable and prevents further corrosion or oxidation. Aluminum reacts with the oxygen in the environment to create a 4-nanometer thick layer on the surface, a process known as passive film formation. This film protects the metal from further oxidation and, therefore, from corroding. Anodized Aluminum is a popular way of adding color and enhancing corrosion resistance. During the anodizing process, oxidation is carefully controlled to produce an extremely stable layer.

Heat Resistance:

- Stainless Steel can be used at higher temperatures than Aluminum.

- Aluminum can become very soft above about 400 degrees Fahrenheit.

Welding:

- Stainless Steel is easier and quicker to weld than Aluminum because Stainless shrinks less upon solidification and expands less when heated.

Cost:

- Since Aluminum is corrosion resistant, it has a very low upkeep cost. Aluminum can be used without any coating in most environments.

- Stainless Steel is similarly low maintenance; however, it is over twice as expensive for a piece of equal strength.

Comparing both metals shows that each metal is suitable for a specific application depending on many factors. When it comes down to Aluminum vs. Stainless Steel, it is important to check the properties of each metal against the requirements of the project you will be working on.

Categories: Cool Stuff