What Is Plasma Cutting? How It Works & Benefits

What is Plasma Cutting?

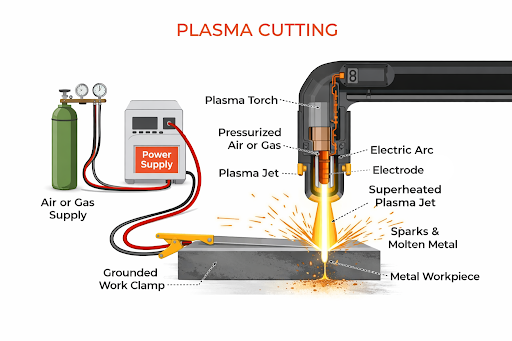

Plasma cutting works by using electricity and compressed gas to create a super-hot, high-velocity jet of plasma that melts metal and blows it out of the cut.

Here’s the process step by step, in plain terms:

1. Power and gas are supplied

A plasma cutter uses:

- an electrical power supply (DC current), and

a gas supply (often compressed air, but sometimes nitrogen, oxygen, or argon mixes)

2. An electric arc is created

Inside the plasma torch:

Electricity jumps from the electrode to the metal workpiece (which is grounded).

This creates an electric arc.

3. Gas turns into plasma

The gas is forced through a small nozzle in the torch.

The electric arc heats the gas to extremely high temperatures (around 25,000°F).

At that temperature, the gas becomes plasma—an electrically conductive, superheated state of matter.

4. The plasma jet cuts the metal

The plasma shoots out of the nozzle as a narrow, high-speed jet.

It melts the metal at the cut line.

The force of the gas blows the molten metal away, creating a clean cut.

5. (For CNC plasma) the torch moves automatically

In CNC plasma cutting:

A computer controls the torch’s movement along the X, Y (and sometimes Z) axes.

The torch follows a programmed path to cut precise shapes, holes, or parts.

Benefits of Plasma Cutting?

Plasma cutting offers a powerful combination of speed, precision, and versatility that makes it a preferred cutting method across many industries. It is capable of cutting a wide range of electrically conductive metals, including carbon steel, stainless steel, and aluminum, while maintaining tight tolerances and clean edges. Compared to traditional cutting methods, plasma cutting delivers faster cut speeds, especially on thicker materials, which helps reduce production time and overall costs. The process also minimizes heat distortion, preserving material integrity and reducing the need for secondary finishing. With the ability to produce complex shapes, tight contours, and repeatable results, plasma cutting is an efficient, reliable solution for fabrication projects that demand accuracy, flexibility, and scalability.

Steel Supply Services

Plasma cutting is just one of the many ways Steel Supply helps customers move projects forward faster and more efficiently. Whether you need precision-cut parts, complex shapes, or production-ready components, our plasma cutting capabilities are designed to deliver clean cuts, consistent quality, and dependable turnaround. Connect with Steel Supply to discuss your project requirements, explore our fabrication services, and get the steel you need cut to your exact specifications and shipped nationwide.

Categories: Services